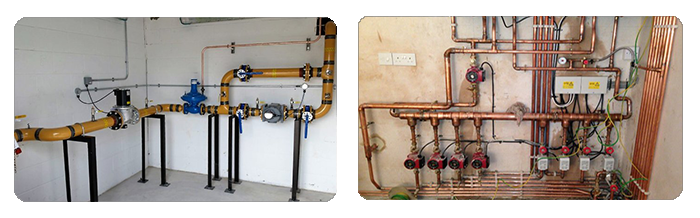

Pipework

Gas

Jackman Peckover is renowned for specialist downstream gas services to suit any requirement pre or post installation, as well as the installation itself.

Our downstream services have been designed and developed to deliver even the most complex and demanding jobs efficiently and effectively and we always create tailored solutions that really satisfy our clients’ needs, no matter how challenging.

We are sure we will be able to help you reach a final decision about exactly what installation you need, by offering specialised pre installation advice or project risk assessment, installation methodology studies or best practice advice.

Once you have awarded the work to Jackman Peckover, we will concentrate a hand-picked installation team that is focused on delivering exactly what is needed from the following services:

- Fully managed solutions

- Pipework

- Live connections and pipework modifications

- Pressure regulators

- Secondary gas metering for energy efficiency

And, after installation is complete and tested, Jackman Peckoverwill maintain, service and update the gas installation as required, under one of our comprehensive maintenance packages. Jackman Peckoverwill deliver the gas installation, metering or specialist pipework service that you need. No matter how big or small, simple or intricate. Contact us anytime to discuss your requirements.

Oil Supply Pipes

Oil supply pipes are a vital part of any oil heating system and it is important that they are installed and maintained correctly to ensure system reliability and safely. Correct installation also helps to avoid the risk of leaks, which can cause pollution and are costly to clean up. This guide applies to pipes that carry fuel to oil fired appliances of up to 45kW output which are located in properties used primarily for domestic purposes.

Domestic Oil Feed Pipes

Domestic oil supply pipes are usually made of plastic-coated soft copper tubing that can be easily manipulated. Steel pipes are not commonly used for domestic installations, but steel pipes can offer additional protection from damage or vandalism. If steel pipes are used, they should not be galvanised and must be painted and maintained to minimise corrosion. Plastic pipe systems are also available but must only be used below ground. Fittings and jointing materials must be suitable for the type of pipe and fuel being used.

Oil Supply Systems

There are two types of oil supply systems; gravity and sub-gravity. Gravity supply systems are arranged so that the pressure of the oil in the tank pushes the oil along the pipe to feed the burner at the appliance. A typical gravity supply would consist of a bottom outlet oil storage tank positioned above the height of the burner. The tank is often elevated to the required height by a platform on top of brick piers. Sub-gravity systems rely on a mechanical device such as an oil de-aerator or lifter to assist the oil in reaching the burner. For satisfactory performance, it is critical that oil supply pipes used with sub-gravity systems are correctly sized.

External/Exposed Pipes

For best performance, oil supply pipework should take the most direct route between the oil tank and burner, while avoiding high and low points in the pipework, the creation of trip hazards, or anything likely to damage the pipe and joints. Pipes must be supported by purpose made clips and attached to permanent structures such as a wall. A garden shed or wooden boundary fence is not classed as a permanent structure because it will deteriorate with age and any movement may damage the pipe and fittings.

Buried Oil Supply Pipes

Directly buried oil supply pipes should be protected against the risk of accidental damage caused by digging. The recommended installation method is as follows: A trench should be excavated to a depth of 450mm 40mm of compacted sand is laid on the bottom of the trench, the oil pipe positioned, and a further 40mm of compacted sand is laid above the pipe Builder’s grade polyethylene is laid above the sand and the trench is then backfilled, positioning an oil line warning marker tape 150mm below the finished ground level. Oil supply pipes should be buried at least 300mm clear of other underground services such as water and electricity. Joints in buried pipework should be avoided if at all possible. If joints have to be made, a permanent means of access for inspection of the joints must be provided.

Entry into Buildings

Where an oil pipe passes through the wall of a building it must be run within a sleeve, such as a larger plastic pipe. Oil supply pipes should not be run underground directly into the interior of a building. Instead the pipe should rise externally to allow a remote acting fire valve to be fitted before it enters the building.

Fire Valves

A fire valve is an essential safety feature of an oil installation, which will stop the supply of oil in the event of a fire or an overheat situation occurring at the appliance. The valve must be located outside the building, before the point of entry, and must be activated by a remote sensor. Existing oil feed pipes that are not accessible outside of the building, and do not have a fire valve, can have one added at the first point where the pipe appears internally. This is not permitted on a new pipe installation, but can improve the safety of an existing installation. Fire valves are also required for externally located boilers.

Annual Inspection

Oil supply pipes must be inspected regularly for general condition and this is often done as part of a routine boilerservice. Any damage, deterioration or leaks from joints should be repaired at the earliest opportunity. For underground pipes, pressure testing is likely to be required.

Steam Pipes and Pipe Sizing

Standards and wall thickness

There are a number of piping standards in existence around the world, but arguably the most global are those derived by the American Petroleum Institute (API), where pipes are categorised in schedule numbers.

These schedule numbers bear a relation to the pressure rating of the piping. There are eleven Schedules ranging from the lowest at 5 through 10, 20, 30, 40, 60, 80, 100, 120, 140 to schedule No. 160. For nominal size piping 150 mm and smaller, Schedule 40 (sometimes called ‘standard weight’) is the lightest that would be specified for steam applications.

Regardless of schedule number, pipes of a particular size all have the same outside diameter (not withstanding manufacturing tolerances). As the schedule number increases, the wall thickness increases, and the actual bore is reduced. For example:

• A 100 mm Schedule 40 pipe has an outside diameter of 114.30 mm, a wall thickness of 6.02 mm, giving a bore of 102.26 mm.

• A 100 mm Schedule 80 pipe has an outside diameter of 114.30 mm, a wall thickness of 8.56 mm, giving a bore of 97.18 mm.

Only Schedules 40 and 80 cover the full range from 15 mm up to 600 mm nominal sizes and are the most commonly used schedule for steam pipe installations.

This Module considers Schedule 40 pipework as covered in BS 1600. Tables of schedule numbers can be obtained from BS 1600 which are used as a reference for the nominal pipe size and wall thickness in millimetres. Table 10.2.1 compares the actual bore sizes of different sized pipes, for different schedule numbers.

In mainland Europe, pipe is manufactured to DIN standards, and DIN 2448 pipe is included in Table 10.2.1.

Water

Jackman Peckover Ltd is able to carry out a range of pipe work services for commercial, local authority, government and light industrial customers.

We are skilled at working in environments such as commercial estates, university campuses, hospitals and military establishments.

A typical job might involve being called in to detect a leak and replace a private water main. This could involve identifying both the leak and the main where the mains might have been laid up to 100 years before

Following on from this and considering the condition of old water mains, water quality and possibly health issues may arise. This in conjunction with the need to balance the demand on the water mains may require replacement with a higher capacity pipe The work would involve the excavation, replacement of the mains and then the reinstatement of the road or other surface.

All parts of the contract require high quality work:

- Correct signage and excavation to protect the operatives and public during the course of the work.

- The installation of the new water pipes due to the fact it will be carrying drinking water

- The backfilling and reinstatement of the surface to ensure that the new or repaired water pipe is protected

For the reinstatement of the road or other surface we are able to use our own resources or call on the services of various professional companies.

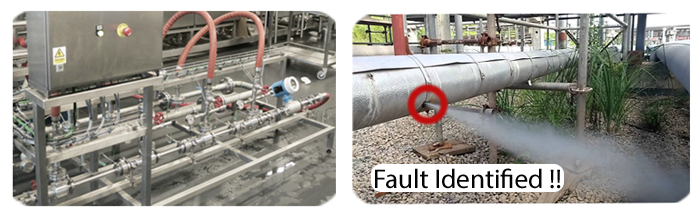

Leak Detection

Identifying the fact of a leak and detecting it rapidly on a large commercial estate is part of our core expertise. We are often called in to conduct water audits, especially when water consumption can appear high.

If you have a leak, rather than dig up the whole pipe, or large parts of it we can identify the location of the leak using both traditional and the latest techniques.

The traditional methods include the use of a rod with an earpiece. The operator simply places the rod tight against the ground and uses the earpiece to listen - it's surprisingly effective to the trained ear!

Compressed Gasses Pipework

Many applications of industrial gases require a gas distribution system to be installed at the user's premises.

Safety considerations require that the main store for the gas, whether this be a cryogenic storage tank or gas cylinders, is located outside in a secure, well ventilated position, away from any sources of ignition. A system of piping is then provided to transfer the gas to the point of use.

Such piping systems must be designed and installed in a manner which complies with relevant legislation, i.e. the Pressure Equipment Regulations 1999 (SI 1999: No. 2001). Once installed they must be documented and maintained in accordance with the Pressure Systems Safety Regulations 2000 (SI 2000: No. 128).

Gas users who need to have a gas distribution system installed on their premises can trust Jackman Peckover as installers who are experienced in installing pipework for industrial gas applications and who are fully conversant with this legislation

Compressed Air Pipework

Avoid pressure loss and problems with our clear information on compressed air piping. Compressed air flows from your compressor to the end-users (pneumatic machines, work stations, etc) through your compressed air piping.

Big deal, a pipe is a pipe, right?! Yes and no. Of course, a pipe is just a pipe. Its purpose is to transport the air without any leakages so you can use it at your machines, air tools, etc. But it’s very important to buy the right kind and size of pipe.

The bigger your compressor and air-demand, the bigger the pipe should be, of course. But how big is big enough? I know lot of difficult formulas and calculations (that can all be found on the internet). It’s all very simple to calculate. Just use your common sense and some basic rules.

What else is important besides size? Your pipes should be strong enough to withstand the pressure and don’t use a 7-bar pipe for a 30 bar system, obviously. Secondly, your pipes should be durable and be suitable for the compressed air (oil free, with oil, maximum temperature, etc).

Also, the layout and installation of the piping is important. There are a few things to keep in mind when installing compressed air piping, like water, rust problems, where to place valves, where to place connections and filters, and many more.

Pressure Drop and Pipe Size

The compressed air piping in your building will always generate some pressure drop. What does this mean? It means that your air users (like air-grinders, pneumatic machines, etc) don’t get the same pressure that is available at your compressor. The air always has some difficulty to pass through the pipes. The longer and smaller the pipes, the harder it is for the air to pass through it. For this reason, it’s important to install big enough piping. Can’t decide between two sizes? Get the bigger one! The more air you use, the bigger the pressure drop is. If you don’t use any air at all (after working hours) there won’t be any pressure drop. Pressure drops are only created when the air flows through the piping. Too small piping is a common problem in factories and workshops which have been expanded over time. They may install a new machine, add extra air tools, etc. Over time, the original piping which was fine at first became too small! Just like a fast growing city with lots of traffic jams, because the roads are still too small.

Different Kinds of Pipe

There are so many different kinds of compressed air pipes on the market these days. It can be a bit confusing. There are steel pipes, plastic pipes, stainless steel pipes and many other materials available in the shops